Half hull boat models originated as practical design tools in 18th-19th century shipbuilding, allowing naval architects to visualize hull shapes and create full-scale construction templates before transitioning to decorative maritime art in the 20th century. Today, custom half hulls serve as sophisticated wall displays commemorating yachts, showcasing yacht design portfolios, and creating elegant nautical décor at scales from 1:12 to 1:48.

The Historical Origins of Half Hull Models

Builder’s Half Models as Design Tools

Before computer-aided design revolutionized naval architecture, shipbuilders and yacht designers relied on physical half models as essential engineering tools. These “builder’s half models” served multiple critical functions in the design and construction process.

The traditional design workflow:

A naval architect or master shipwright would begin with sketches and calculations, then translate designs into a three-dimensional half model. This model—representing one side of the vessel since hulls are symmetrical—allowed visualization impossible from two-dimensional drawings alone.

Functional applications:

Design development:

-

Testing hull proportions and visual balance

-

Refining sheer lines, bow profiles, and stern shapes

-

Evaluating aesthetic qualities before construction commitment

-

Experimenting with variations quickly and economically

Client presentations:

-

Showing proposed designs to yacht owners three-dimensionally

-

Demonstrating design concepts more effectively than drawings

-

Earning client approval before costly construction began

-

Creating tangible representations for comparison shopping

Construction template creation:

-

Models built in “lifts” (horizontal layers) representing waterlines

-

Loftsmen used lifts to create full-scale patterns for frame shapes

-

Transferring dimensions from model to lofting floor

-

Ensuring accurate hull shape during construction

The most sophisticated builder’s models were constructed to precise scales (commonly 1:12 or 1:24) using hardwoods, then sliced horizontally into lifts. Each lift could be lifted away from the model, traced, and used to develop full-scale frame patterns for construction.

Historic collections:

Major maritime museums preserve builder’s half models documenting yacht design evolution. The Herreshoff Marine Museum in Bristol, Rhode Island houses hundreds of builder’s models from the legendary Herreshoff Manufacturing Company. The New York Yacht Club maintains models of classic America’s Cup defenders including J-Class giants of the 1930s.

These working tools became decorative art only after their practical purpose was served. Builders would mount finished models on backboards, add brass nameplates, and present them to yacht owners at delivery—beginning the tradition of half hull models as commemorative art.

Transition to Decorative Art

The mid-20th century shift from half models as engineering tools to decorative maritime art occurred as naval architects adopted drawing tables, then computers. Physical half models were no longer necessary for design work, but their aesthetic appeal and maritime heritage ensured continued popularity.

The decorative half hull emerged:

-

Yacht owners commissioned models of their boats for wall display

-

Yacht clubs mounted fleets of member boats creating gallery walls

-

Designers maintained portfolio collections showcasing hull forms

-

Maritime enthusiasts collected historic vessel models as art

This transition refined half hull construction. While builder’s models emphasized accuracy for measurement extraction, decorative models prioritized visual beauty—smooth finishes, elegant backboard presentations, optional deck details enhancing realism.

Modern custom half hulls from Abordage continue this dual heritage—engineering accuracy combined with artistic presentation creating sophisticated maritime décor.

Half Hull Construction Techniques

Traditional Plank-on-Lift Construction

Authentic half hull models use construction methods echoing full-size wooden boatbuilding:

The lift-building process:

1. Lofting and design transfer:

-

Hull lines taken from naval architect’s drawings or existing boats

-

Dimensions scaled to selected model scale (commonly 1:24)

-

Horizontal “waterlines” established at regular vertical intervals

-

Each waterline becomes a “lift” in the model

2. Lift template creation:

-

Waterline shapes drawn on pattern material

-

Templates cut precisely representing each horizontal slice

-

Stacked templates create hull shape when assembled

3. Material selection:

-

Premium hardwoods: basswood (easy shaping), mahogany (traditional), teak (marine appropriate)

-

Wood must be kiln-dried preventing later movement

-

Grain direction selected for strength and appearance

-

Thickness determined by lift spacing and model scale

4. Lift cutting and shaping:

-

Templates traced onto wood blanks

-

Each lift cut to rough shape on bandsaw or scrollsaw

-

Lifts stacked and glued creating rough hull form

-

Entire assembly hand-shaped with files, rasps, and sandpaper

5. Finishing:

-

Progressive sanding from coarse (80-grit) to fine (400-grit)

-

Hull must be perfectly smooth before finishing

-

Multiple coats of sanding sealer fill grain

-

Final varnish or paint application

This labor-intensive process produces half hulls with proper hull curves, authentic construction, and museum-quality appearance.

Modern Precision Methods

Contemporary half hull builders like Abordage supplement traditional methods with precision technology:

CNC machining:

-

Computer-controlled routers rough-shape lifts from CAD data

-

Ensures perfect accuracy to original boat’s lines

-

Dramatically reduces rough shaping time

-

Hand-finishing still completes the process

Laser-cut deck details:

-

Deck patterns, hatches, and features laser-cut from wood or plastic

-

Microscopic accuracy impossible by hand

-

Allows intricate detail at small scales

-

Manually applied and finished after cutting

3D modeling and visualization:

-

Hull forms verified digitally before physical construction

-

Clients preview models via renderings before work begins

-

Ensures accuracy and client satisfaction

-

Databases preserve designs for future reference or reproduction

Traditional skills remain essential:

-

Hand-sanding creates smooth, fair surfaces

-

Paint and varnish application requires master craftsman skill

-

Deck detail installation demands patience and precision

-

Final assembly and mounting purely handwork

The marriage of traditional craftsmanship and modern precision delivers custom half hull models combining historical authenticity with contemporary accuracy.

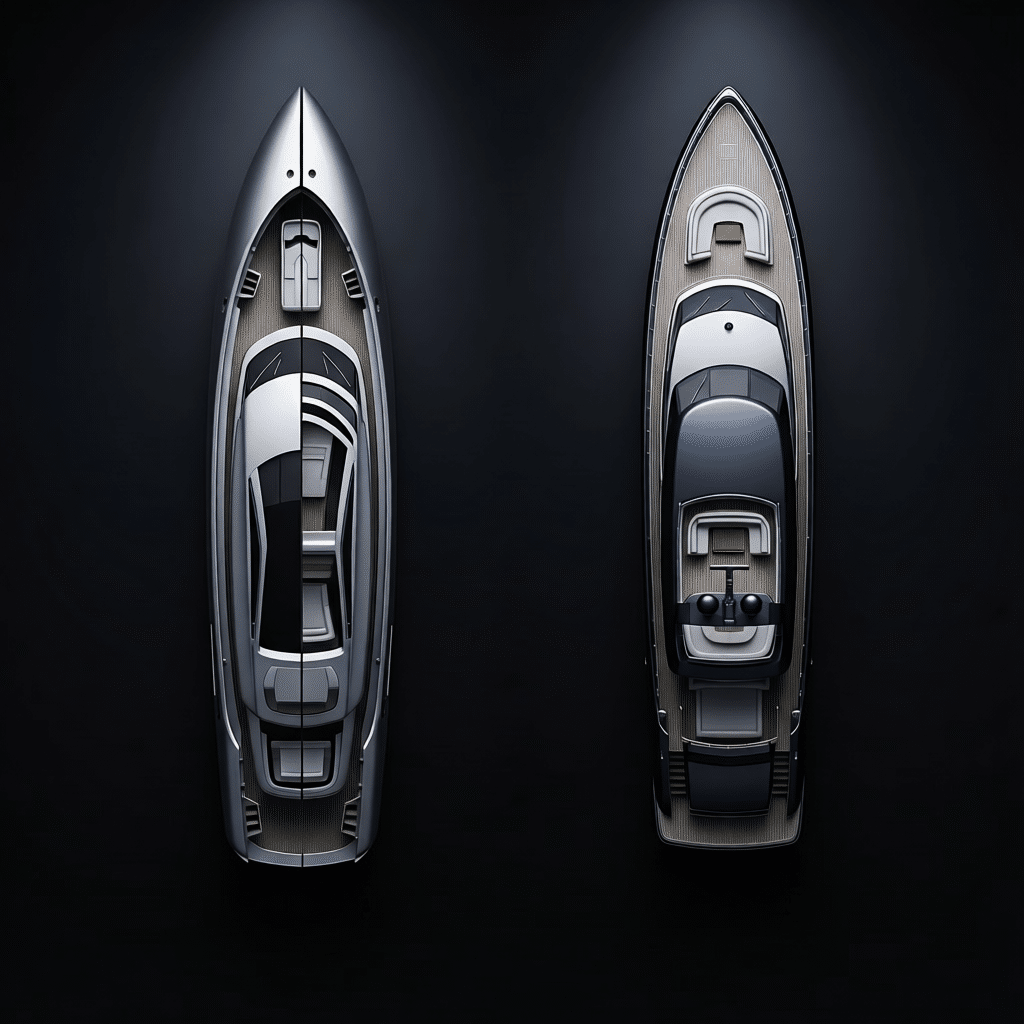

Detail Levels and Construction Styles

Half hull models are available in three primary detail configurations:

Flush deck (no details):

The hull form is complete, but the deck surface remains smooth without any fittings or details.

Advantages:

-

Emphasizes pure hull lines and proportions

-

Most affordable construction option

-

Fastest production timeline (8-10 weeks typical)

-

Classic builder’s model aesthetic

-

Perfect for racing yacht underbodies

Best applications:

-

Classic sailing yachts with beautiful sheer lines

-

Racing designs where hull form defines the boat

-

Budget-conscious projects

-

Collections emphasizing multiple boats over individual detail

Investment range: $800-$1,500 typical for 1:24 scale

Cabin and cockpit only:

Dimensional cabin trunks and cockpit areas are added showing deck camber and structural profiles.

Advantages:

-

Shows deck profile and camber

-

Reveals coach roof and cockpit proportions

-

Balances detail with reasonable cost

-

Suitable for most yacht types

Best applications:

-

Cruising sailboats with distinctive cabin designs

-

Powerboats with flybridge or cabin structures

-

Moderate detail preference

-

Traditional yacht presentation

Investment range: $1,200-$2,200 typical for 1:24 scale

Full deck details:

Complete deck hardware, rigging, stanchions, and fittings accurately represent the actual vessel.

Advantages:

-

Museum-quality representation

-

Shows complete yacht configuration

-

Impressive visual impact

-

Maximum personalization with vessel-specific details

Components included:

-

Miniature deck hardware (cleats, winches, hatches)

-

Stanchions and lifelines

-

Mast and boom (sailing vessels) with some rigging

-

Cockpit instrumentation and steering wheels

-

Canvas work (biminis, dodgers)

-

Deck patterns and non-skid textures

Best applications:

-

Custom yacht commissioning where specific details matter

-

Yacht designer portfolios showcasing complete designs

-

Premium gifts and commemorative pieces

-

Vessels with unique or innovative deck layouts

Investment range: $1,800-$3,500 typical for 1:24 scale

Browse the half hull models collection viewing examples across all detail levels.

Backboard Design and Presentation

Traditional Backboard Styles

The backboard completes the half hull presentation, significantly impacting overall aesthetic:

Classic hardwood backboards:

Materials:

-

Mahogany: Traditional choice, rich reddish-brown tones

-

Teak: Marine-appropriate, golden-brown color

-

Oak: Prominent grain, lighter color, traditional

-

Walnut: Dark, sophisticated, contemporary appeal

Edge treatments:

-

Raised beveled edges creating dimensional frames

-

Routed edge profiles adding traditional detail

-

Simple chamfered edges for clean lines

-

Flat edges for minimalist presentations

Finishes:

-

Hand-rubbed varnish enhancing wood grain

-

Satin or gloss polyurethane for durability

-

Oiled finishes for natural appearance

-

Stained to match interior décor

Dimensions:

-

Typically 4-6 inches wider than hull length

-

Height proportional to hull depth plus clearance

-

Thickness 3/4″ to 1-1/2″ depending on model size

-

Larger models benefit from thicker boards providing visual weight

Contemporary Backboard Options

Modern interiors often benefit from simpler, cleaner presentations:

Painted backboards:

White lacquer:

-

High-gloss or satin finishes

-

Gallery-style museum presentation

-

Emphasizes model, minimizes background

-

Perfect for modern/contemporary interiors

-

Works beautifully with classic and modern yacht designs

Black lacquer:

-

Dramatic contrast, especially with white-hulled boats

-

Sophisticated, formal appearance

-

Popular for professional offices and yacht clubs

-

Creates strong visual impact

Custom colors:

-

Match specific interior color schemes

-

Coordinate with yacht club colors or team colors

-

Brand-appropriate for corporate displays

Alternative materials:

Acrylic/Plexiglas:

-

Ultra-modern minimalist aesthetic

-

Clear or frosted options

-

Lightweight for easier wall mounting

-

Contemporary yacht designs

Metal frames:

-

Brushed aluminum or stainless steel

-

Industrial/modern aesthetic

-

Marine-appropriate materials

Nameplate and Documentation

Engraved nameplates add professionalism and documentation:

Plate materials:

-

Brass: Traditional, classic appearance, tarnishes over time

-

Stainless steel: Modern, maintenance-free, never tarnishes

-

Aluminum: Lightweight, contemporary, various finishes available

Information included:

-

Yacht name in prominent position

-

Yacht designer and/or builder

-

Length overall (LOA) and model scale

-

Year launched or commissioned

-

Owner name (optional)

-

Special achievements or history (optional)

Placement:

-

Bottom center of backboard most common

-

Upper corner for modern presentations

-

Integrated into backboard design

-

Separate plate mounted near model if grouped display

Engraving methods:

-

Traditional rotary engraving: deep, permanent, classic

-

Laser engraving: precise, modern fonts, graphics capable

-

Etching: chemical process, fine details possible

Nameplates transform half hulls from anonymous models to documented vessels with history and provenance.

Modern Applications of Half Hull Models

Yacht Owner Commemorations

The most common use of custom half hulls celebrates yacht ownership:

Reasons yacht owners commission half hulls:

Vessel documentation:

-

Preserving memory of beloved boat after sale

-

Commemorating significant cruises or passages

-

Documenting custom features or modifications

-

Creating family heirlooms passing to next generation

Display locations:

-

Home offices and libraries

-

Yacht club lockers and personal spaces

-

Primary residences in nautical-themed rooms

-

Vacation homes with maritime character

-

Aboard current yachts (sometimes including previous boats)

Emotional connections:

Yacht ownership creates powerful memories—maiden voyages, family adventures, challenging passages, quiet anchorages. A custom half hull preserves these experiences, serving as conversation starter sharing sailing stories with guests and family.

Scale selection:

Most yacht owner half hulls range from 1:24 to 1:32 scale, producing models 15-24 inches long for typical 30-60 foot yachts. Larger yachts may use 1:48 scale managing overall size while retaining impressive presence.

Browse custom half hull options for various yacht types and styles.

Yacht Designer and Architect Portfolios

Naval architects and yacht designers use half hull collections showcasing design work:

Portfolio applications:

Client presentations:

-

Physical representations more impactful than drawings

-

Demonstrate hull form expertise and aesthetic sense

-

Allow clients to visualize proposed designs

-

Differentiate designer from competitors relying solely