Commissioning a custom boat model in 2026 involves selecting scale, providing accurate documentation, choosing construction style, and working with experienced craftsmen to create a museum-quality replica of your vessel. The process typically takes 8-16 weeks from initial consultation to delivery, with prices ranging from $800 to $15,000+ depending on size and detail level.

Why Commission a Custom Boat Model?

Custom boat models serve multiple purposes beyond decoration. Yacht owners commission replicas to commemorate their vessels, yacht designers use them for client presentations, and maritime enthusiasts preserve naval heritage through accurate reproductions. In 2026, the demand for personalized nautical memorabilia has grown significantly as high-net-worth individuals seek unique ways to celebrate their maritime passion.

Popular Custom Model Applications

-

Yacht owner commemorations: Preserve the memory of a beloved vessel

-

Corporate gifts: Prestigious presents for maritime industry partners

-

Yacht brokerage displays: Sales tools showcasing available inventory

-

Designer portfolios: Physical representations of naval architecture work

-

Maritime museums: Educational exhibits and collection pieces

The Custom Model Commissioning Process

Step 1: Initial Consultation and Documentation

The commissioning journey begins with gathering comprehensive information about your vessel. Quality documentation ensures accuracy in every detail of the final model.

Essential materials to provide:

-

High-resolution photographs from multiple angles (bow, stern, port, starboard, aerial)

-

Original boat plans or naval architect drawings if available

-

Deck layout specifications including helm station, seating, and electronics

-

Color schemes for hull, deck, canvas work, and upholstery

-

Boat name, home port, and registration details

-

Reference materials for logos, graphics, or custom features

The more detailed your documentation, the more accurate your custom boat model will be. Professional photographs taken in good lighting conditions are particularly valuable for capturing deck details, hardware finishes, and color accuracy.

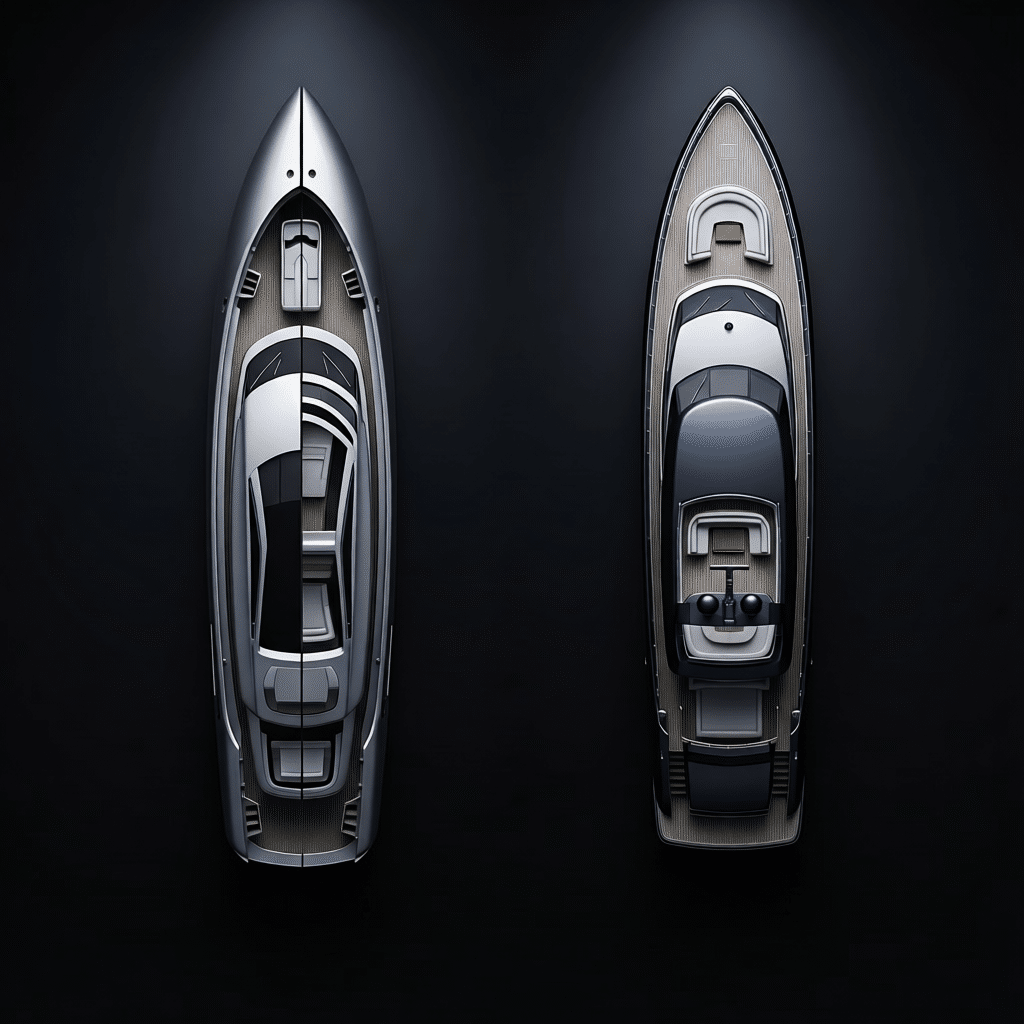

Step 2: Choosing Your Model Type and Scale

Three primary construction styles are available, each suited to different display preferences and budgets:

| Model Type | Best For | Typical Scales | Price Range |

|---|---|---|---|

| Half Hull Models | Wall display, traditional aesthetic, line study | 1:24, 1:32, 1:48 | $800-$3,500 |

| Desk Models | 360° viewing, detailed rigging, office display | 1:35, 1:40, 1:50 | $2,500-$8,000 |

| Large Scale Models | Yacht clubs, corporate lobbies, museums | 1:12, 1:16, 1:20 | $8,000-$15,000+ |

Scale selection considerations:

-

Display space: Measure your available wall or shelf area before selecting scale

-

Detail level: Larger scales (1:12-1:24) allow for intricate deck details, electronics, and rigging

-

Budget: Smaller scales generally cost less but may sacrifice detail visibility

-

Viewing distance: Models viewed from across a room can be smaller scale than desk displays

For sailing vessels, consider whether you want full rigging details or a simplified presentation. Custom sailboat models with complete standing and running rigging create dramatic displays but require more delicate handling.

Step 3: Materials and Construction Methods

Abordage craftsmen utilize premium materials selected for durability and authenticity:

Hull construction options:

-

Plank-on-bulkhead: Traditional method using kiln-dried mahogany, teak, or other hardwoods

-

Hand-laid resin: Modern technique for complex hull shapes with gelcoat finish

-

ABS and wood combination: Hybrid approach balancing strength and aesthetics

Deck and detail materials:

-

Custom-made brass castings for cleats, stanchions, and hardware

-

Chrome-plated brass for modern yacht fittings

-

Laser-cut wood components for precise deck patterns

-

Hand-sewn canvas for biminis, dodgers, and sail covers

-

Miniature electronics and gauges replicating actual helm stations

All materials undergo rigorous quality control before construction begins. Hulls are hand-sanded to achieve smooth finishes, then protected with marine-grade varnishes or polyurethane paints matching your vessel’s exact colors.

Step 4: Review and Refinement

Professional model builders provide progress updates throughout construction:

-

Week 2-3: Hull shaping review with photographs

-

Week 5-7: Deck layout approval before final assembly

-

Week 10-12: Pre-finishing inspection for color matching

-

Week 14-16: Final review before shipping

This collaborative approach ensures the finished model meets your exact specifications. Changes are easier and less costly when addressed early in the process, so active engagement during review stages is essential.

Step 5: Display and Presentation

Proper mounting and display protection maximize the longevity and visual impact of your model:

Half hull mounting options:

-

Traditional wooden backboards in mahogany, oak, or walnut finishes

-

Contemporary white or black lacquered boards for modern interiors

-

Custom-engraved brass nameplates with vessel details

-

Optional display cases for dust protection

Desk model bases:

-

Solid wood pedestals in various finishes

-

Acrylic cradles for minimalist presentations

-

Rotating bases for 360° viewing

-

Museum-quality glass display cases with UV protection

Consider the lighting in your display location. Models with high-gloss finishes may create reflections under direct spotlights, while matte finishes work well in various lighting conditions.

2026 Trends in Custom Boat Models

The custom model industry reflects broader yachting trends:

Sustainability focus: Eco-conscious owners request FSC-certified woods and low-VOC finishes, mirroring the yacht industry’s shift toward sustainable materials.

Technology integration: Some clients commission models with LED lighting systems, embedded QR codes linking to vessel histories, or augmented reality companion apps.

Corporate branding: Charter companies and yacht builders increasingly use custom models as marketing tools at boat shows and in sales offices.

Classic yacht revival: Growing interest in vintage designs drives demand for models of iconic builders like Chris Craft, Hinckley, and Herreshoff classics.

Pricing and Timeline Expectations

Investment in a custom boat model varies based on complexity:

Budget considerations:

-

Simple half hull (20-24″ length): $800-$1,500

-

Detailed half hull with deck details: $1,500-$3,500

-

Desk model with full rigging: $2,500-$6,000

-

Large-scale exhibition model: $8,000-$15,000+

Timeline factors:

-

Standard projects: 10-14 weeks

-

Complex multi-hull designs: 14-18 weeks

-

Rush orders (when available): 6-8 weeks with premium

-

Custom display case fabrication: Add 2-3 weeks

Peak commissioning seasons (spring and holiday periods) may extend timelines, so plan accordingly if your model is intended as a gift or for a specific event.

Working with Abordage Master Craftsmen

Since 1989, Abordage has specialized in creating museum-quality custom replica boat models for private owners, yacht designers, and shipyards. The company’s facility includes dedicated departments for hull construction, brass casting, painting, laser cutting, and chrome plating—all under one roof for complete quality control.

Each craftsman brings decades of experience in maritime modeling, ensuring accurate proportions, authentic details, and professional finishing. The engineering department develops custom models using original plans and high-precision equipment, translating full-size vessels into perfect miniature replicas.

To begin your custom boat model project, visit the custom model request form or contact the Abordage team directly. Include your vessel specifications, preferred scale, and timeline requirements for a detailed quotation.

Frequently Asked Questions

How accurate will my custom model be?

Accuracy depends on documentation quality. With comprehensive photos and plans, Abordage achieves 95-98% accuracy in proportions, colors, and details including specific hardware, electronics, and custom features.

Can you model a boat that no longer exists?

Yes, provided adequate reference materials are available. Historical photographs, surviving plans, or similar vessel examples enable reconstruction of boats no longer afloat.

What’s the difference between a kit model and a custom commissioned model?

Kit models are mass-produced generic representations, while custom models are handcrafted replicas of your specific vessel with exact colors, features, and personalization.

Do you offer international shipping?

Yes, Abordage ships custom boat models worldwide with specialized packaging ensuring safe delivery. International shipping typically adds 1-2 weeks to delivery timelines.